Case history

Statoil: Tune

Drilling and completion

Drilling and completing with formate brines delivers four problem-free wells and 100% of recoverable reserves over ten years.

Tune is a gas-condensate field located about ten kilometres west of the Oseberg Field Centre in the northern part of the Norwegian sector of the North Sea. Water depth in the area is approximately 95 metres. The reservoir lies at a depth of around 3,400 metres and consists of Middle Jurassic sandstones of the Brent Group, divided into several inclined fault blocks. Reservoir thickness is 100 metres. At the time of development it was classified by the operator as high temperature (131°C) and on the border of high pressure (525 bar).

The field is developed with four wells in a subsea template. Reservoir permeability is between 10 and 200 mD with porosity of 16%. Tune’s recoverable reserves were estimated by the Norwegian Petroleum Directorate (NPD) to be 18.3 billion m3 of gas and 3.3 million m3 of condensate.

Horizontal drilling with openhole completions

A potassium formate drill-in fluid with density of 1.65 g/cm3 (13.8 lb/gal) was used to drill and complete the 8 reservoir sections of four wells in Tune from 2000 to 2001 [Nottveit, 2003]. The wells were drilled horizontally through the reservoir and completed in open hole with 300-micron single-wire-wrapped screens. Reservoir section lengths were between 350 and 900 metres. Lower completions were run in the formate drilling fluid and upper completions in clear cesium/potassium formate brine. The wells were also successfully suspended for six to twelve months in cesium/potassium formate brine pending completion of the production pipeline.

Production payback

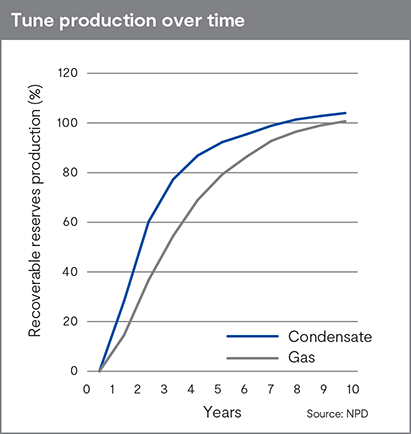

Tune was brought onto production in November 2002. Good well-flow performance was recorded at production start-up and, in June 2003, the field was reported to be producing 12.4 million m3/day of gas and 23,000 bbl/day of condensate [Karlsen, 2003]. The wells and residual filter-cake lining the open boreholes cleaned up naturally during early production [Karlsen, 2003] and no filter-cake removal or well stimulation treatments were required. Production records on the NPD website indicate that by the end of year seven of full production the four Tune wells had produced 92% of recoverable gas reserves and more than 97% of estimated recoverable condensate reserves. Seventy percent of recoverable gas and 87% of recoverable condensate were produced after only four years, while 100% recovery was reached within ten years.

This case history and all others are downloadable here.

Literature

Nottveit, A. (2003, June 23–24 June). Tune Case: Experience from Drilling and Completion Using Formate-Based Fluids.

Proc., IQPC Drilling & Completion Fluids Conference, Aberdeen, UK.

Karlsen, S. B. (2003, June 23–24 June). Tune Case: Experience from Cleanup and Production Using Formate-Based Brines as Drilling/Completion Fluids, Proc., IQPC Drilling & Completion Fluids Conference, Aberdeen, UK.

Downs, J. D. (2010, January). A Review of the Impact of the use of Formate Brines on the Economics of Deep Gas Field Development Projects. Proc., SPE Deep Gas Conference and Exhibition, Manama, Bahrain. SPE-130376-MS. doi.org/10.2118/130376-MS.

Downs, J. (2011, October 24). Life Without Barite: Ten Years of Drilling Deep HPHT Gas Wells With Cesium Formate brine. Proc., SPE/IADC Middle East Drilling Technology Conference and Exhibition, Muscat, Oman. SPE-145562-MS. doi.org/10.2118/145562-MS.

Olsvik, G., Howard, S. and Downs, J. (2013, June). The Long-Term Production Performance of Deep HPHT Gas Condensate Fields Developed Using Formate Brines. Proc., SPE European Formation Damage Conference & Exhibition, Noordwijk, The Netherlands. SPE-165151-MS. doi.org/10.2118/165151-MS.