Case history

bp: Raven

Gravel-pack completion

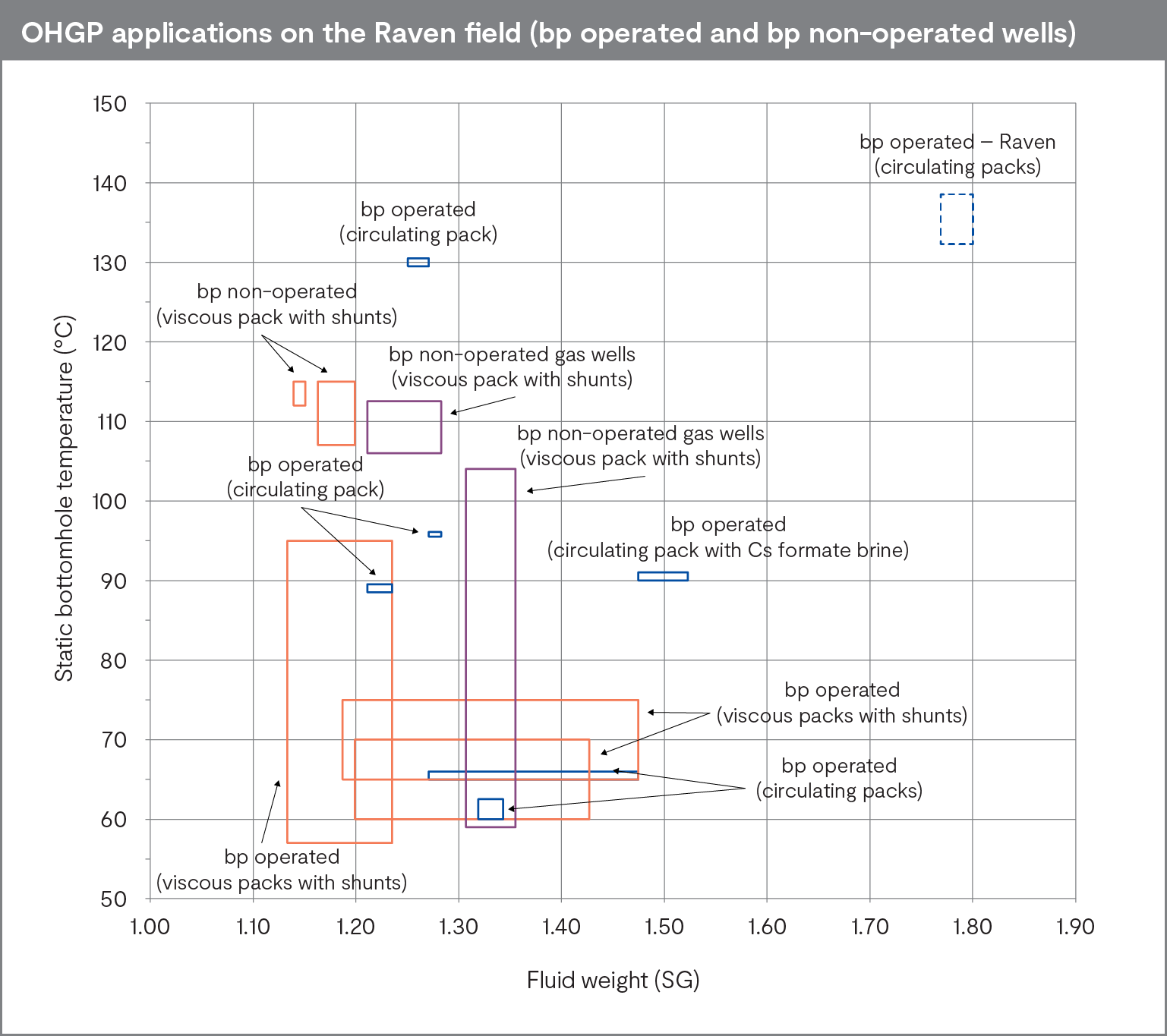

Raven: bp sets a global record by achieving successful openhole gravel pack completion of several high-pressure high-temperature (HPHT) wells, utilising a carrier fluid with an unparalleled application density of 1.80 to 1.84 g/cm3 (15.0 to 15.3 lb/gal).

The operator, bp, selected openhole gravel-pack (OHGP) completions with sand screens, facilitated by high-density cesium/potassium formate brine, to guarantee production across the entire reservoir interval. This optimises long-term productivity and ensures well integrity over the expected 15-to-20-year life of the field.

Seven wells were packed with 100% efficiency. Skin factors were significantly lower than expected and production indices are excellent. As of June 2023, Raven is producing approximately 600 MMscf/d with a peak potential of 900 MMcf/d and 30,000 b/d of condensate.

Challenges

To maintain sand control as reservoir depletion can make the formation sand-prone; avoid wellbore instability from potential completion fluid incompatibility with shale; and prevent formation or completion damage.

Solution

A formation-friendly, high-density blend of cesium and potassium formate designed to operate in HPHT conditions and successfully facilitate openhole gravel-pack completions.

Results

Successful openhole gravel packing of seven wells. Testing across the entire reservoir sand interval showed minimal or no formation damage, with skin factors considerably lower than predicted. Wellbore stability remains excellent, as do production indices.

(15.0–15.3 lb/gal)

Raven is an HPHT gas condensate field located 70 km offshore Egypt in the West Nile Delta, with water depths of around 650 to 700 metres (2,133 to 2,297 feet).

Cased or open hole?

Sand production prediction modelling shows that sand control completions are optimal for Raven due to the high drawdown and depletion expected, especially as the wells are located offshore with no possibility for intervention after subsea hook-up, nor tolerance for sand production.

Cased-hole gravel-pack (CHGP) completions were reviewed but ruled out. Since high levels of formation damage had been observed from post-perforation fluid-loss control pills and re-establishing connectivity with the perforation tunnels was difficult, CHGP was expected to cause skin-factor and flux constraints.

Cased-hole frac-pack (CHFP) completions were not logistically possible as there were no stimulation vessels or CHFP services available in the region.

In a less challenging field, completing with gravel pack in open hole is an obvious solution. OHGP completions are relied upon by bp and other operators, and are proven to enhance production, reduce well construction costs and simplify operations. However, this technique had not been attempted in wells with temperatures and pore-pressure gradients as high as Raven. The situation is further complicated by a narrow margin between the pore-pressure and fracture-pressure gradients, restricting the overbalance to around 120 psi (8.3 bar). Notwithstanding these challenges, bp demonstrated a readiness to implement this completion technique, contingent upon finding a fluid that met the specifications.

Fluid selection

Conventional gravel-pack fluids used in wells with relatively low pressures and temperatures cannot withstand high temperatures and/or are unable to mix effectively in the high-density completion brine necessary for Raven.

Without a formation-compatible fluid capable of withstanding the challenging HPHT conditions and HSE requirements, completing in open hole is impossible. The pore pressure necessitates a high-density fluid that exceeds the pressurised crystallisation temperature range of chloride and bromide brines, and other such fluids. Although of correct density, zinc bromide is too hazardous to use due to the health, safety and environmental requirements set by bp. So, a relatively benign brine that meets the operational demands and HSE criteria of Raven is needed.

In response, a cesium/potassium formate brine was put through its paces: bp’s tests demonstrated that the brine met or surpassed all technical requirements. Cesium/potassium formate brine exhibits a low crystallisation temperature, is nondamaging to the formation, eliminates completion damage and provides thermal stability to biopolymeric additives. As well as being reservoir compatible, the cesium/potassium formate brine is non-corrosive. It is also highly compatible with downhole and surface equipment, and treatment fluids. Furthermore, its environmental and safety credentials align with bp’s requirements.

Which gravel pack?

Initially, an alternate-path viscous gravel-pack technique was preferred. This was due to highly reactive shale intervals across the formation, and risk of formation fracturing during the gravel-pack pumping operation in the narrow pore-pressure fracture gradient (PPFG) window. This may have resulted in premature screen-out and failure.

The major technical challenge with the alternate-path OHGP was the development of a new viscous gravel-pack carrier fluid that maintains stable viscosity at high temperatures, but subsequently breaks down after pumping to enable good well cleanup and strong productivity.

Laboratory tests were conducted to evaluate the carrier fluid’s performance, including fluid rheology tests at different temperatures, mapping of gravel suspension and breakdown characteristics, compatibility with formation fluid and full stack-up coreflood tests.

Following this evaluation, a yard trial was conducted where the selected gravel-pack fluid was mixed and pumped on a large scale using the actual pumping equipment employed offshore. The yard trial revealed several concerns relating to the design and operational complexity of the gravel-pack fluid system.

The requirement for a viscous gravel pack for Raven was re-assessed, and a circulating pack using non-viscosified brine selected as the preferred gravel-pumping technique. Subsequently, the well design was simplified and descoped to minimise operational risks.

The results are in

Seven of eight wells were successfully gravel packed. Well testing showed skin factors that were significantly lower than the +10 predictions. Well eight had an incomplete gravel pack due to non-fluid-related issues, which resulted in a higher skin factor.

Well testing confirmed production across the entire reservoir sand interval, showing that the cesium/potassium formate fluid caused minimal to no formation or completion damage.

The skin factors were significantly lower than expected given the very high transmissibility of the Raven reservoir (158,000–368,000 mDft/cP) and the associated low drawdowns required to meet target gas flow rates. The very low levels of formation damage are attributed to the rigorous design and subsequent execution-phase QA/QC of the reservoir drilling and completion fluids.

The cesium/potassium formate brine maintained stable hydrostatic pressure in the hole for enhanced well control, which improves safety by eliminating the risk associated with sag in solids-weighted fluids.

Formate brine losses as a percentage of total working brine volume ranged from 3.3% to 5.8% for each completion, including the gravel-pack carrier fluid volume. When averaged over all wells in the completion campaign, total losses were only 4.7% of total working formate brine volume. This is outstanding for a clear brine openhole completion.

Conclusions

High-density, non-damaging 1.80 to 1.84 g/cm3 (15.0 to 15.3 lb/gal) cesium/potassium formate brine enabled successful OHGP operations on the Raven HPHT field for bp. Such a high-density fluid in OHGP operations is unprecedented and expands the field-proven operating envelope for challenging gravel-pack operations.

Key factors for the successful implementation of the Raven completion campaign include rigorous planning and the inclusion of the operations team and service providers in the well-programme planning phase.

The team at bp is delighted with the results of the campaign and provides the following comment in paper OTC-29549-MS: “All completed wells demonstrated excellent well performance results with very low completions skin. The well flow-back and test results exceeded expectations, indicating the entire reservoir sand was contributing to flow, demonstrated greater than predicted Productivity Index (PI) with minimal skin damage. Sand control integrity was achieved with full gravel pack efficiency.”

This case history and all others are downloadable here.

Literature

Tahirov, T., El-Wakeel, W., Mohiuldin, G., Whaley, K., Jackson, P.,

Olinger, M., Mansour, M. and Elshafaie, I. (2019, April 26). Sand

Control Completions for Raven Field in Egypt. Proc., Offshore Technology Conference, Houston, Texas, USA. OTC-29549-MS.

doi.org/10.4043/29549-MS.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies allows us to process data such as browsing behaviour or unique IDs on this site. Not consenting or withdrawing consent may adversely affect certain features and functions, such as downloading the Formate Technical Manual or MSDSs.