Why conventional coreflood tests on formate fluids fail and what can be done

Oslo, Norway – 30 May 2024

"A typical coreflood test run on formate fluids can be a waste of time and money. Even worse, it may result in the wrong fluid choice, which itself can severely impact delivery of hydrocarbon reserves," says Siv Howard, R&D Manager, Sinomine Specialty Fluids.

Siv Howard has been at the forefront of formate fluids research for decades, first for Shell and Hydro Formates, and now as head of research and development for Sinomine. She is responsible for developing a tailor-made coreflood testing procedure for these unique fluids, which has recently been revised based on new research.

Before we look at the latest study and what it means to the test procedure, let’s take a step back and ask ourselves "what is coreflood testing and why does it matter?"

What is coreflood testing?

Coreflood testing is an often-used laboratory method to help evaluate and qualify well construction fluids for a field development.

Schlumberger defines it as: "A laboratory test in which a fluid or combination of fluids is injected into a sample of rock. Objectives include measurement of permeability, relative permeability, saturation change, formation damage caused by the fluid injection, or interactions between the fluid and the rock." 1

A goal of all testing is to try and replicate reservoir conditions as closely as possible. If a coreflood test laboratory fails to do this, then the results generated are most likely incorrect, and a fluid can be wrongly disqualified.

Set up to fail

As coreflood test laboratories are used to dealing with solids-laden muds, tests are naturally set up to suit these fluids. There should be little surprise that when these procedures are then applied to solids-free or low-solids formate fluids, with very different properties, they fail.

"We’ve seen formate fluids ruled out time and again for field developments due to incorrect coreflood tests," says Siv Howard. “This is frustrating to put it mildly, when we know how well these fluids perform in the field.”

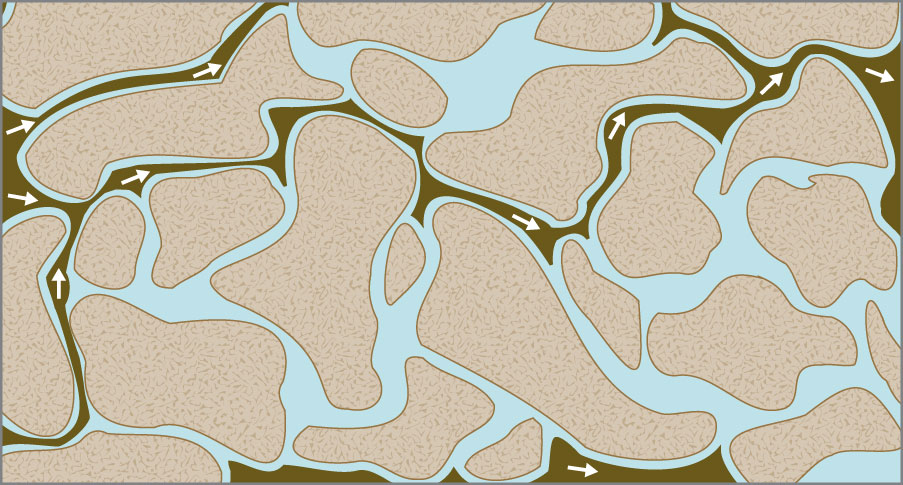

Why are traditional coreflood tests unsuited to formate fluids?

Formate fluids can appear to reduce effective permeability to oil and gas in traditional coreflood tests due to so-called ‘filtrate retention’. This occurs when raised levels of water-based fluids are left inside the core after filtrate invasion, as a result of failure to fully displace the fluids with hydrocarbons during drawdown.2 The original effective permeability of the core to hydrocarbons is typically measured at residual water saturation, where the pores of the rock sample contain approximately 20% to 25% formation water. Any increase in water saturation above original residual levels during coreflood testing, caused by aqueous filtrate invasion and failure to fully remove that filtrate during drawdown, decreases the effective permeability to oil and gas. The laboratory may then draw the wrong conclusion, and incorrectly predict that the test fluid will permanently reduce reservoir permeability to hydrocarbons.

Just an illusion

Filtrate retention only gives an illusion of failure. It is invariably a laboratory artefact caused by poor experimental design and execution, notably a failure to simulate real field conditions. Excess filtrate or formation water left in the core by inadequate and unrealistic drawdown regimes after flooding with formate fluids is mobile and temporary. Simply restoring the core to the same water saturation level it had before exposure to the formate brine or filtrate, recovers full permeability in many coreflood tests.

In other cases, where the filtrate is difficult to displace out of the core after being trapped behind a thin filter cake, a mild cleanup with formation water may return the core to its initial oil and gas permeability.

Furthermore, heavy formate filtrate is known to drain from the near wellbore by gravity. By not permitting enough time and using a test cell with physical constraints not present in the reservoir, the filtrate is unable to drain and failure is guaranteed.

Martin Linge – a case in point

Before TotalEnergies drilled the first well in its Martin Linge field in the North Sea, the company ran conventional coreflood tests on low-solids 2.0 g/cm3 (16.7 lb/gal) cesium/potassium formate drilling fluid and an oil-based mud weighted with micronized barite. Return permeabilities for the formate fluid were poor – just 15% and 14% for 3.5 D and 934 mD cores – resulting from, what was defined by the test laboratory, as ‘water blockage’, which originated from filtrate retention.

Based on these discouraging coreflood test results, TotalEnergies drilled three wells into the Martin Linge reservoir using the micronized-barite-weighted oil-based mud system. Two were suspended for several weeks before cleanup, while cleanup was attempted immediately after drilling for the third well. The wells, which were all fitted with 230-μm expandable sand screens, failed to clean up, most likely due to screen plugging.

TotalEnergies was forced to re-evaluate its fluid choice before drilling the fourth well. The option of cesium/potassium formate fluid was reevaluated, and three new coreflood tests were conducted based on Sinomine’s recommended coreflood procedure. Return permeabilities were 50% to 60%, which improved to around 70% to 80% after external filter-cake removal and spindown.3

Based on these findings, cesium/potassium formate fluid was chosen for the fourth well. Results were excellent. The well outperformed the other three, cleaning up to a PI twice as high as in the previous wells, in much shorter time and with no indication of formation or completion damage.

This field case clearly demonstrates the importance of correct coreflood testing for formate fluids. For more details on this case, please reference the Coreflood Testing report.

Time changes everything

In some coreflood tests, it has been difficult to fully displace the formate filtrate using drawdown procedures and conditions routinely applied in the oil industry. During recent tests on formate drilling fluids for particularly low-temperature applications, removal of the filtrates, which are viscosified with various biopolymers, proved exceptionally challenging. It was suspected that the viscosifying biopolymers in the formate filtrates were not being fully thermally degraded at the low temperatures. This triggered research into how temperature affects the rate of thermal degradation of biopolymers, such as xanthan and starch.

The results of the research show that exposure time significantly impacts the level of thermal degradation of xanthan gum in different brines and waters.4 Given enough time, all tests show an almost complete breakdown of biopolymers in formate brines, even down to the lowest test temperature of 124°C (255°F).

Zhao Andersen, Senior Associate Scientist at Sinomine, explains the significance of the results: "With this new understanding of biopolymer self-breaking time, we believed we were getting closer to explaining some of the historical coreflood testing problems with formate fluids. We already knew from bp’s analysis of cesium formate performance in its Rhum field5 that wells drilled and/or completed with formate fluids clean up gradually over time. We have, of course, made efforts to clean up the core for longer, but looking back, we now understand that we never gave these attempts enough time."

Updated coreflood procedure for formate fluids

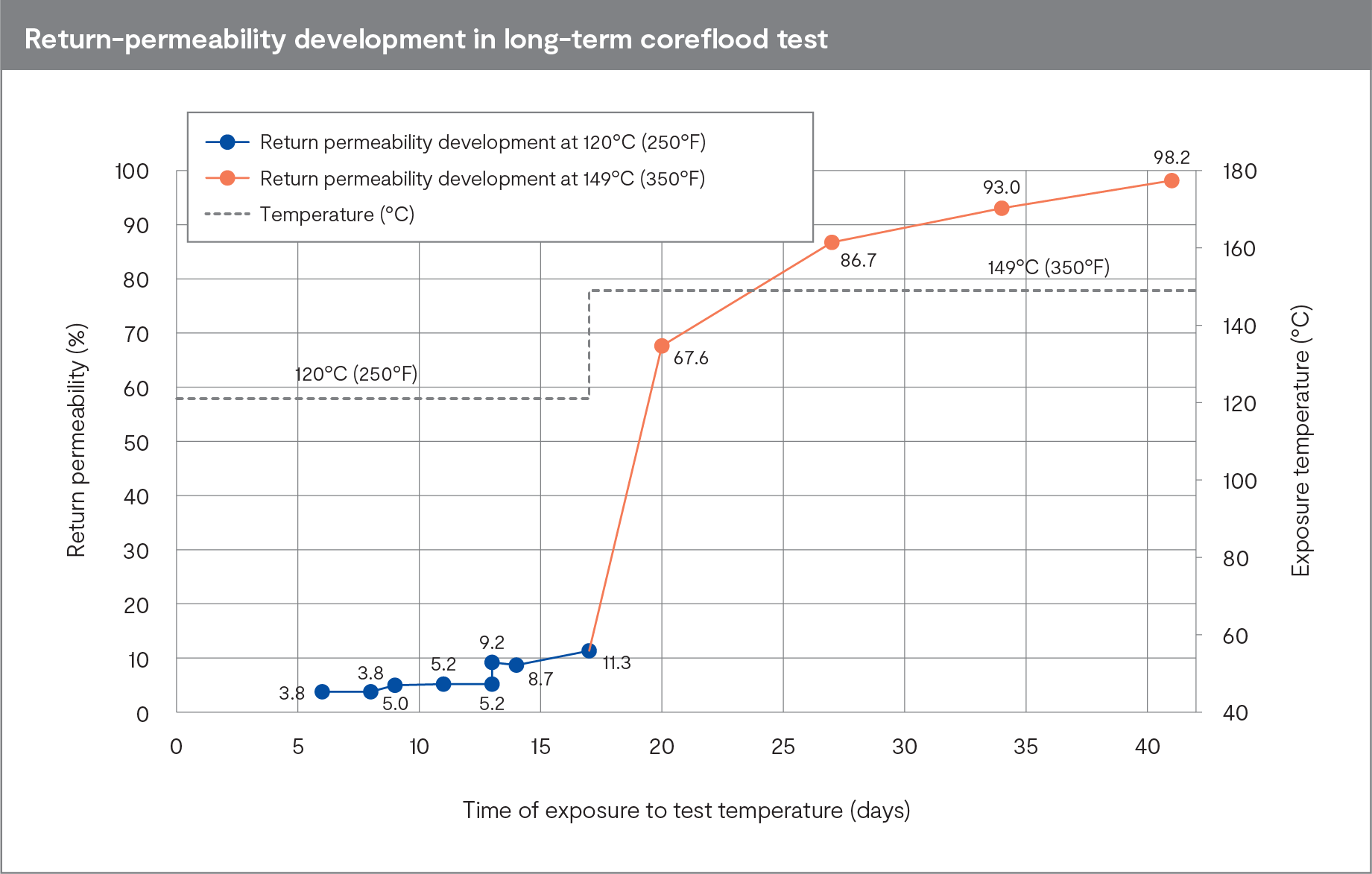

Based on the new understanding of biopolymer self-breaking rates and the hypothesis that these can significantly affect the outcome of coreflood testing, a revised long-term coreflood test was designed and trialed. Multiple suspension periods were introduced at two different temperatures and permeability was measured after each suspension period. The test continued as long as permeability improvements were observed. The results were stunning, with the core cleanup rate increasing from 3% to 98% during the extended test duration of 41 days. This is perhaps not difficult to understand when the supposed 'damage' is caused by filtrate retention. It is naturally harder for filtrate to escape when hindered by unbroken biopolymers, or when these polymers increase its viscosity.6

Biopolymer self-breaking time can, of course, affect all drilling and completion fluids viscosified by polymers or where biopolymeric fluid-loss control agents are used. However, the problem is greater in formate fluids due to their ability to stabilise polymers at very high temperatures. This is an important property, which allows these benign, non-damaging polymers to be used at very high temperatures.

"With this new knowledge, we have made a significant modification to our coreflood testing procedure for formate drilling fluids. The updated recommendations have now been included in a new version of our Coreflood Testing report and in Formate Technical Manual section B10 Compatibility with the reservoir," explains Siv Howard.

Are coreflood tests necessary?

In conclusion, the question can be asked whether coreflood tests are necessary for all field developments? Interestingly, the operator with the most experience doesn't think so. During 100-plus operations, Equinor has come to understand how these high-performance brines deliver superior rates of production and maximise asset potential. Equinor's fluid experts have seen how several poor results from traditional coreflood testing are in stark contrast to strong field performance. The result? The company no longer recommends coreflood testing of formate fluids for their typical applications.7

References

- glossary.slb.com/terms/c/coreflooding.

- van der Zwaag, C. H., Olsen, H. and Lohne, A. (2010, February 10). Significance of Selected Set-up Parameters in Return Permeability Measurements Used for Formation Damage Quantification. Proc., SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, Louisiana, USA. SPE-127994-MS. doi.org/10.2118/127994-MS.

- Jøntvedt, E., Fjeldheim, M., Løchen, J., Howard, S., Leon, S., Busengdal, C. and Richard Gyland, K. (2018, February 7). Deployment of Cesium Formate Drill-In and Openhole Completion Fluid in the Martin Linge High Pressure, High Permeability Gas Reservoir Enhances Total’s Operational Efficiency and Radically Improves Well Performance. Proc., SPE International Conference and Exhibition on Formation Damage Control, Lafayette, Louisiana, USA. SPE-189550-MS. doi.org/10.2118/189550-MS.

- Anderson, Z., Ioannou, A., Howard, S. and Downs, J. (2023, June 29). Understanding and Managing the Natural Self-Breaking Behaviour of Xanthan in Reservoir Drill-In, Completion and Workover Fluids. Proc., SPE International Conference on Oilfield Chemistry, The Woodlands, Texas, USA. SPE-213822-MS. doi.org/10.2118/213822-MS.

- Roy, A. M., Twynam, A. J., Parke, J., Morrison, A. and Downs, J. (2008, May 5). An Evaluation of Perforating Techniques and Use of Caesium Formate Kill Pills to Maximise Productivity in HPHT Gas Wells and Minimise HSE Risks. Proc., Offshore Technology Conference, Houston, Texas, USA. OTC-19242-MS. doi.org/10.4043/19242-MS.

- Howard, S. (2024, February 21). Long-term Coreflood Testing with Biopolymers – A Laboratory Investigation Showing How Return Permeability Improves From 0 to 100 Percent by Getting a Critical Parameter Right. Proc., SPE International Conference and Exhibition on Formation Damage Control, Lafayette, Louisiana, USA. SPE-217909-MS. doi.org/10.2118/217909-MS.

- Fleming, N., Moldrheim, E., Teigland, E. and Mathisen, A. M. (2020, February 20). Well Productivity Evaluation and Implications for the Significance of Formation Damage: Oseberg Main Case History. Proc., SPE International Conference and Exhibition on Formation Damage Control, Lafayette, Louisiana, USA. SPE-199266-MS. doi.org/10.2118/199266-MS.